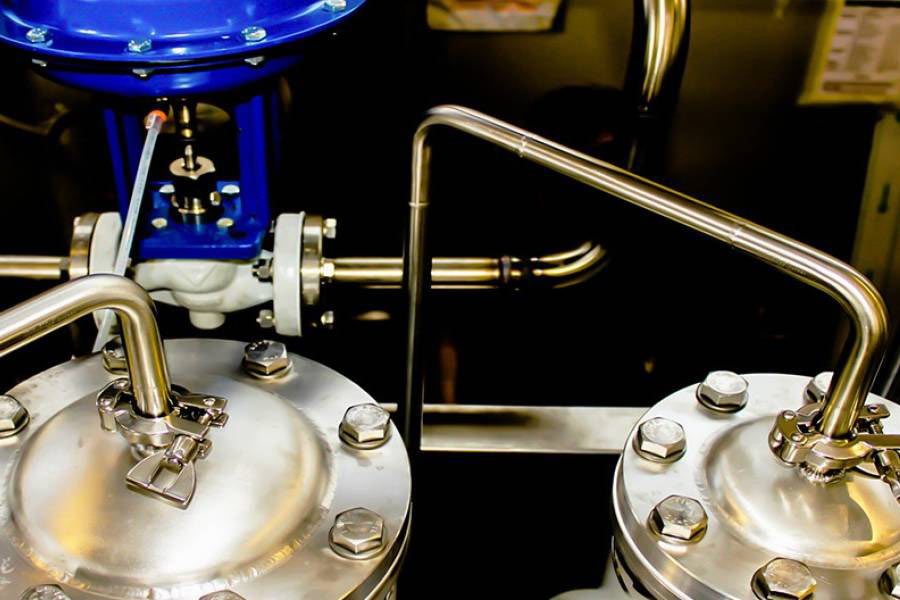

Pre-treatment & RO-EDI Generation

Reducing downtime to improve your bottom line

Pick a Service

Purified Water, WFI and Pure Steam Generation

Honeyman has built-up a long-standing reputation as the industry’s leading expert in purified water, WFI and pure steam generation.

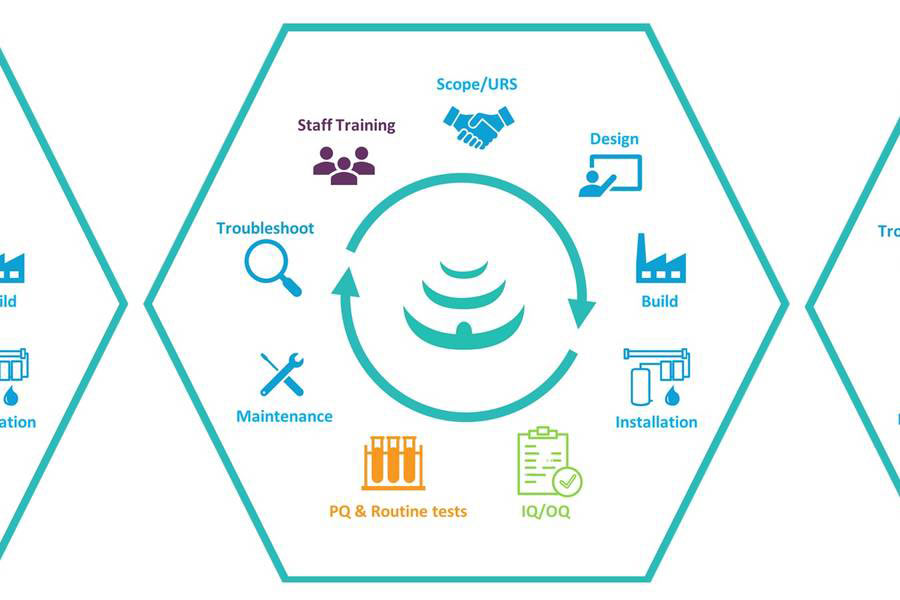

Our first step in any successful project is being able to clearly define outcomes and goals. What do you need from your water system? Whilst that may seem a simple question, getting to the correct answers isn't always as straight forward as it seems. A badly specified system can put unnecessary constraints on site operations and can be costly to rectify once installed.

Honeyman Water can offer standard and bespoke solutions to suit your requirements:

At Honeyman Water, we can join you at the beginning of your project; whether a new system or amending / upgrading a current system. We can help you plan and ask the right questions to enable the correctly installed system within your facility. Following a detailed consultation with the Honeyman team, we can efficiently produce a precise and clearly defined URS that all project stake holders can buy into.

Honeyman Water can offer the following services:

- Scope / URS

- Design

- Water / Steam generation equipment supply

- System Built

- Install

- IQ / OQ

- PQ / Routine testing

- Maintenance

- Troubleshooting

Utilising our decades of experience in quality water systems, you can be confident of receiving the very best system for your facility, meeting your requirements whilst ensuring regulatory compliance.

Download PDF: Pharmaceutical Water Brochure

To discuss your water or steam requirements, please contact us with your details and a brief introduction, so we can arrange a call back at a time convenient to you.

Our Customers: